RUNNERBREAKER for Aluminum Alloy

RUNNER BREAKER FOR ALUMINUM ALLOY

Runner breaker machine for aluminum alloy

RUNNERBREAKER for Aluminum Alloy (5371KB) |

A lineup of long-awaited aluminum alloy dedicated machines for runner breakers

The object to be crushed is thrown in from the slot and crushed with a fixed blade and a moving blade that moves back and forth. We have newly manufactured a special machine for aluminum alloy that applies the basic structure of the conventional runner breaker.

Aluminum has a low melting point among metals and is easy to process, so its characteristics are significantly different from those of cast iron. Soft and highly viscous aluminum alloys were difficult to crush with conventional casting blades. However, as a result of many years of experience and technology, and through trial and error, we succeeded in establishing a mechanism for crushing aluminum alloys while cutting them. (Patented)

By adjusting the shape of the blade and the engagement of the two blades according to the material of the material to be crushed, it can be crushed to the size suitable for melting efficiency.

In addition, the number of components has been reduced compared to the crusher for castings, achieving both weight reduction and cost reduction.

Target crushed material

- Aluminum alloy (aluminum ingot, magnesium alloy, copper alloy, etc.)

* Please contact us for crushed objects not listed. We have a wide range of crushing capacity (processing amount) to meet your needs.

*For pig iron castings, etc., Conventional RUNNERBREAKER is supported.

Features

In the past, processing costs were high, so return materials were used as they were for the melting and recycling processes.

By crushing to the optimum size for melting with the special RUNNERBREAKER for aluminum alloy, it is possible to reduce the cost of remelting.

Furthermore, by reducing the volume, storage and transportation will be more efficient.

Return material

Defective products, discarded products, weirs, sprue cups, etc.

RUNNERBREAKER

Small crushing with a crusher dedicated to aluminum alloy

Redissolve

Commercialization / recycling

- Various crushing cycles

The crushing stroke and cycle time can be set by PLC.

You can easily adjust the crushing size and capacity. - Can be installed in the line

By setting the PLC, continuous operation is possible in a completely unmanned state, so it can be installed in the line. - Reduction of maintenance costs

Uses a high manganese blade with excellent wear resistance using the latest technology. Due to its simple structure, there are few failures and maintenance is easy. - Reduction of running cost

Since the fan-shaped motion of the blade during crushing applies the principle of leverage, power consumption is low for the output.

Microcomputer control panel

Line installation example

High manganese knife

High durability cylinder

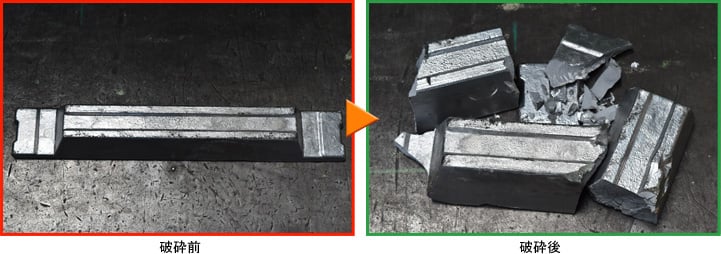

Crushing example

Aluminum alloy return material Crush to optimal size for redissolution

Aluminum die-cast weir Example of volume reduction rate <42.4% reduction>

Aluminum alloy ingot Dissolution efficiency UP

Crushing video

Aluminum ingot crushing test

Case-shaped work crushing test

Spec.

Format | ALP450K | ALP600K | ALP900K | ALP1200K | ALP1500K | ||

Overall length (mm) (A) | 1,750 | 2,300 | 2,750 | 2,900 | 4,250 | ||

Overall width (mm) (B) | 650 | 850 | 1,150 | 1,550 | 1,950 | ||

Overall height (mm) (C) | 900 | 1,100 | 1,200 | 1,400 | 1,900 | ||

Opening dimensions (mm) (W) | 450 × 400 | 600 × 600 | 900 × 900 | 1,200 × 1,200 | 1,500 × 1,500 | ||

Crushing capacity (kg / h) | Aluminum alloy | 400 | 1,200 | 2,000 | 3,200 | 4,200 | |

Cylinder maximum output (t) | 10 | 50 | 50 | 50 | 150 | ||

Maximum pressure (Mpa) | 12 | 12 | 12 | 12 | 12 | ||

Dimensions

- The drawings are under development and may differ from the actual ones.

- The crushing capacity varies considerably depending on the shape of the plan and the material of the crushed material.

- Please contact us for specifications and layout of hydraulic units, control panels, etc.

- This specification is subject to change without notice.

- Please contact us for any other changes or additions to the specifications.